Technical Documentation

Technical Documentation for Battery Connection Solutions

Discover detailed technical specifications for Wellgo's industry-leading battery connection components, including Copper Busbars and Nickel Strips, customized for diverse applications such as electric vehicles, energy storage systems, and consumer electronics. Each product page is equipped with downloadable spec sheets for precise technical details.

Why Choose Wellgo's Components?

- Custom Design: Tailored copper and nickel components to match battery arrangements, including 18650, 21700, and 26650 cells.

- Material Options: Choose from plated nickel, pure nickel, or copper for optimized conductivity and durability.

- Precision Engineering: Spot welding for thicknesses beyond 1mm ensures a secure and reliable connection.

- Versatile Applications: Ideal for use in automotive, renewable energy, and portable electronics.

Access Comprehensive Documentation

For complete technical details, every product features a dedicated Spec Sheet PDF, which you can easily download from the product details page. This documentation includes precise information on center distances, thickness variations (0.1mm–1.5mm), and compatibility with brackets or honeycomb structures.

Customization & Support

Need a unique design for your project? Contact us to discuss bespoke solutions tailored to your specifications. Whether you require oval holes for spot welding or special configurations, our team is ready to assist.

Detailed Technical Insights for Superior Battery Connections

-

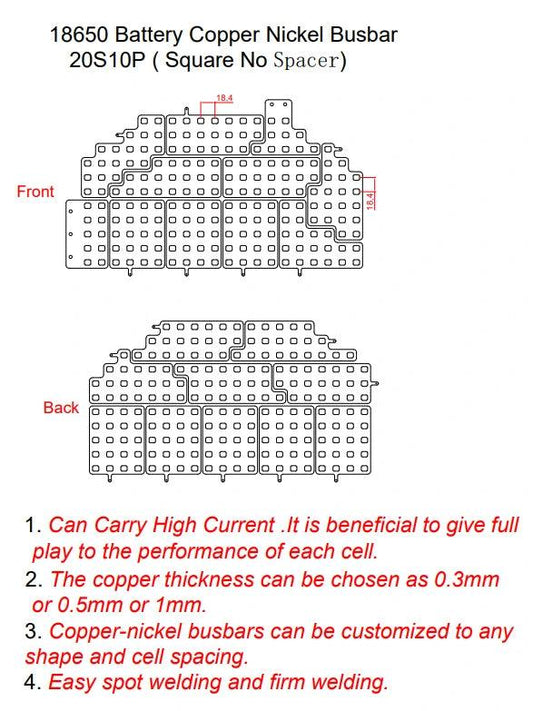

18650 Customized Copper Nickel Busbar 20S10P for Lithium-Ion Battery Connections in Electric Bicycle - No Cell Spacer

厂商:Wellgo Battery常规价格 来自 $53.00 USD常规价格 -

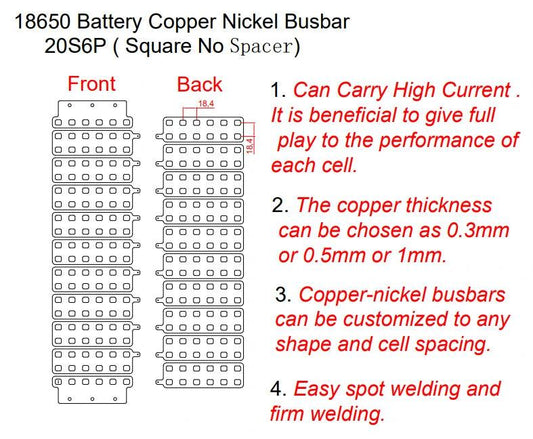

18650 Customized Copper Nickel Busbar 20S6P for Lithium-Ion Battery Connections in E-bike - No Cell Spacer

厂商:Wellgo Battery常规价格 来自 $34.70 USD常规价格 -

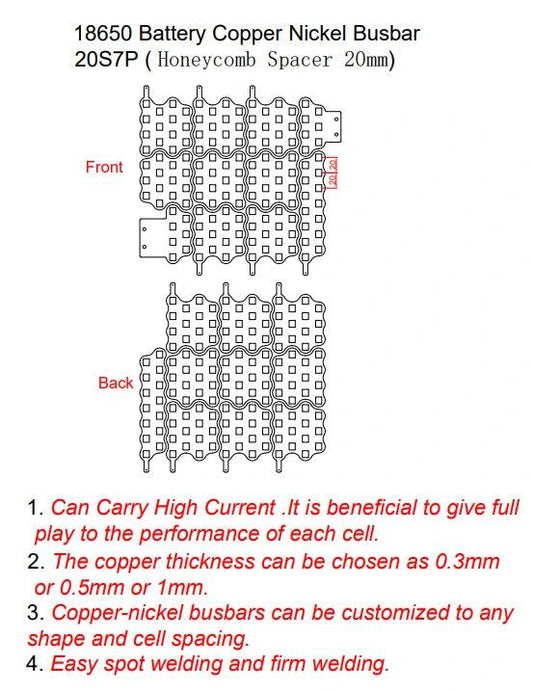

18650 Customized Copper Nickel Busbar 20S7P for Lithium-Ion Battery Connections in E-bike Honeycomb Cell Spacer Center - Distance 20mm

厂商:Wellgo Battery常规价格 来自 $39.30 USD常规价格 -

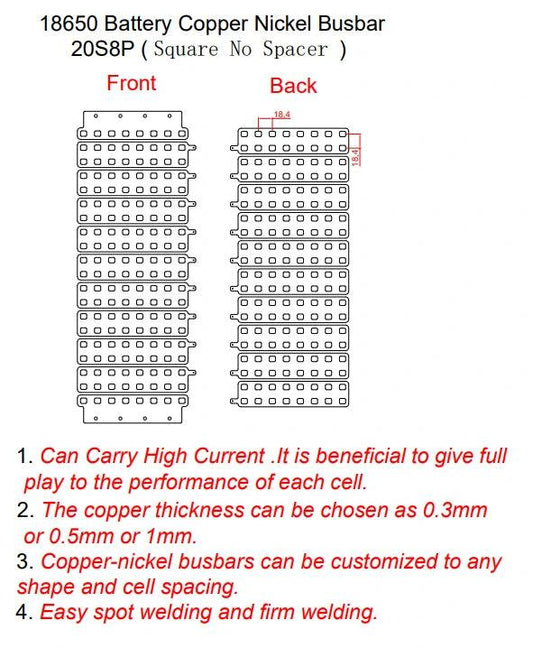

18650 Customized Copper Nickel Busbar 20S8P for Lithium-Ion Battery Connections in Electric Bicycle - No Cell Spacer

厂商:Wellgo Battery常规价格 来自 $43.80 USD常规价格

Contact Us

"Connect to Thrive, Power Your Drive."

Wellgo is a trusted provider of high-performance battery connection solutions, specializing in custom-designed copper and nickel composite busbars, battery tabs, and precision connectors.

Precision Manufacturing and High-Quality Battery Connections

-

High-Quality Copper-Nickel Battery Busbars

Learn MoreWellgo’s copper-nickel composite busbars are engineered for superior conductivity and longevity, ideal for high-demand battery applications such as electric vehicles and energy storage.

-

Customized Laser Cutting Solutions

Wellgo’s skilled technicians use advanced laser cutting software to deliver customized designs, meeting unique requirements for each battery connection solution.

-

Advanced Laser Cutting for Precision Components

Our cutting-edge laser cutting technology ensures high precision in shaping nickel and copper battery connectors, providing consistent quality and fit.

Latest News

查看全部-

The Future of Busbar Technology in EV and Renew...

The future of busbar technology is reshaping how electric vehicles (EVs) and renewable energy systems deliver power efficiently and safely. With rising demand for high-current, compact, and sustainable energy solutions,...

The Future of Busbar Technology in EV and Renew...

The future of busbar technology is reshaping how electric vehicles (EVs) and renewable energy systems deliver power efficiently and safely. With rising demand for high-current, compact, and sustainable energy solutions,...

-

Export Guide: Shipping Copper Busbars to the US...

This article serves as a practical export guide for copper busbars shipped to the US and EU, covering customs, documentation, tariffs, and compliance requirements. It explains key regulations such as...

Export Guide: Shipping Copper Busbars to the US...

This article serves as a practical export guide for copper busbars shipped to the US and EU, covering customs, documentation, tariffs, and compliance requirements. It explains key regulations such as...

-

Copper Busbar Customization Options: Plating, B...

This article explores key copper busbar customization options — including plating, bending, and insulation — to enhance performance and reliability in battery busbar applications. It explains how surface coatings like...

Copper Busbar Customization Options: Plating, B...

This article explores key copper busbar customization options — including plating, bending, and insulation — to enhance performance and reliability in battery busbar applications. It explains how surface coatings like...