Lithium Battery Recycling: How to Recycle Lithium Batteries Responsibly and Sustainably

Share

1. Why Lithium Battery Recycling is Essential?

Recycling lithium batteries is essential because:

Mitigating Environmental Risks

Lithium batteries contain hazardous materials like lithium, cobalt, and nickel. Without proper disposal, these substances can contaminate soil and water. Recycling prevents harmful pollution and protects ecosystems.

Conserving Resources

Lithium and cobalt are limited resources with high extraction costs. Recycling recovers these materials, reducing the need for additional mining and preserving natural reserves.

Supporting Circular Economy Goals

Recycling enables the reuse of materials from old batteries to produce new ones. This minimizes waste and promotes sustainable manufacturing.

2. Benefits of Lithium Battery Recycling

Reducing Carbon Footprint

Recycling consumes less energy than mining and processing raw materials, cutting greenhouse gas emissions.

Preventing Toxic Waste

Safe recycling handles hazardous substances, eliminating environmental and health risks from improper disposal.

Fostering Innovation

Recycled materials like cobalt and lithium reenter manufacturing processes, driving advancements in battery technology and cleaner energy solutions.

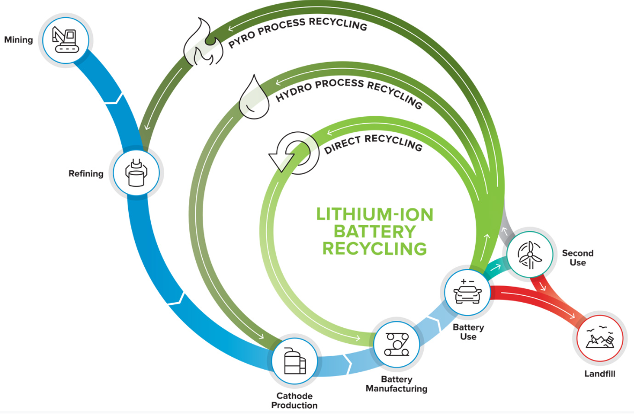

3. How Are Lithium Batteries Recycled?

Collection and Sorting

Lithium batteries are collected through programs or drop-off points and then sorted by type and condition:

-

Battery Collection Points: Recycling facilities gather batteries from consumers.

-

Sorting by Type: Batteries are categorized by chemistry (e.g., lithium-ion, lithium-polymer) for optimal recycling.

-

Source:

Safe Packaging and Transportation of Lithium Batteries for recycling: What You Need to Know

Disassembly

- Manual Dismantling: Workers disassemble battery packs into cells and components.

-

Automated Processes: Machines separate battery components efficiently and safely.

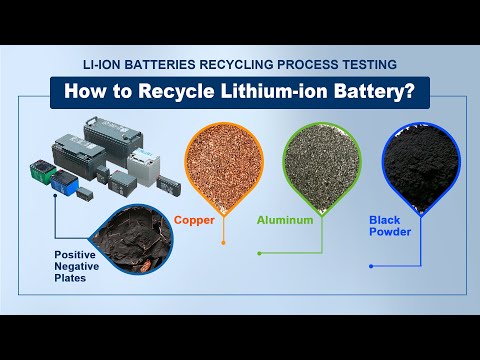

Material Recovery

-

Recycling processes recover valuable materials:

- Thermal Treatment: Heats batteries to extract metals.

- Hydrometallurgical Processes: Chemicals recover lithium, cobalt, and nickel.

- Pyrometallurgical Processes: High temperatures smelt metals for reuse.

Examples:

- Lithium: Used in new batteries.

- Cobalt and Nickel: Recycled for industrial applications.

- Copper and Aluminum: Reused in manufacturing.

Neutralization of Toxic Substances

Hazardous materials, like electrolyte solutions, undergo neutralization to ensure safe disposal and meet environmental standards.

4. Environmental Stewardship in Lithium Battery Recycling

Legislative Support

Governments enforce recycling mandates to ensure eco-friendly disposal:

- EU Battery Directive: Enforces recycling quotas.

- US EPA Regulations: Govern hazardous waste management.

Corporate Responsibility

Many manufacturers adopt Extended Producer Responsibility (EPR) to manage product lifecycles. For example, Wellgo Battery runs take-back programs to recycle their products.

- Learn more: Wellgo’s custom battery busbar.

Innovations in Recycling

Advances like direct recycling and closed-loop systems enhance efficiency and sustainability:

- Direct Recycling: Preserves battery-grade materials, reducing energy use.

- Closed-Loop Recycling: Ensures no material is wasted, optimizing resource use.

Source: World Economic Forum's Insight on Circular Economy.

Applications of Recycled Materials

Recycled battery materials find applications in various sectors:

- New Batteries: Recovered lithium and cobalt are used to produce new batteries.

- Industrial Uses: Metals like copper and nickel serve in construction and manufacturing.

- Electronics: Plastics and other recovered materials are repurposed in gadgets.

5. Visualizing the Impact of Recycling

| Material | Recovery Rate (%) | Recycled Applications |

|---|---|---|

| Lithium | 95% | New batteries |

| Cobalt | 90% | Electronics and energy storage |

| Aluminum & Copper | 98% | Electrical and manufacturing |

6. How You Can Participate in Lithium Battery Recycling

Find Local Recycling Programs

Dispose of batteries through specialized recycling programs or drop-off locations.

Choose Eco-Friendly Products

Support brands using recycled materials in their manufacturing.

Advocate for Responsible Practices

Encourage businesses and policymakers to prioritize battery recycling and sustainable energy initiatives.

Conclusion

Recycling lithium batteries is a critical step in protecting our planet and advancing sustainability goals. By understanding the recycling process, its benefits, and how recycled materials are repurposed, we can all contribute to a greener future.

Join the Conversation

What are your thoughts on lithium battery recycling? Share your insights, questions, or suggestions in the comments below!