Certifications & Standards

Wellgo takes pride in delivering high-performance battery connection solutions that meet international standards. Our commitment to quality is supported by a state-of-the-art manufacturing facility and comprehensive certifications.

Manufacturing Excellence

- Modern Facilities: Equipped with advanced machinery, Wellgo ensures precision in every production process.

- Expert Team: Highly trained professionals oversee each step to maintain superior quality.

- Streamlined Production: From design to assembly, our processes are optimized for efficiency and reliability.

Comprehensive Certifications

- ISO 9001: Certified for quality management systems to ensure consistent excellence.

- CE & RoHS: Compliance with safety and environmental standards for global acceptance.

- UL Standards: Guaranteed reliability and safety for critical applications.

- Material Assurance: Every batch is rigorously tested for purity and performance.

Application Versatility

- Lithium-Ion Batteries: Designed for 18650, 21700, and custom battery packs.

- Electric Vehicles: Perfectly suited for high-performance EV battery systems.

- Renewable Energy: Reliable for solar and wind energy storage solutions.

Why Choose Wellgo?

- Quality-Controlled Production: Strict inspection standards ensure defect-free products.

- Customization Options: Tailored solutions to meet specific client requirements.

- Global Reach: Trusted by industries worldwide for durable and innovative products.

Detailed Technical Insights for Superior Battery Connections

-

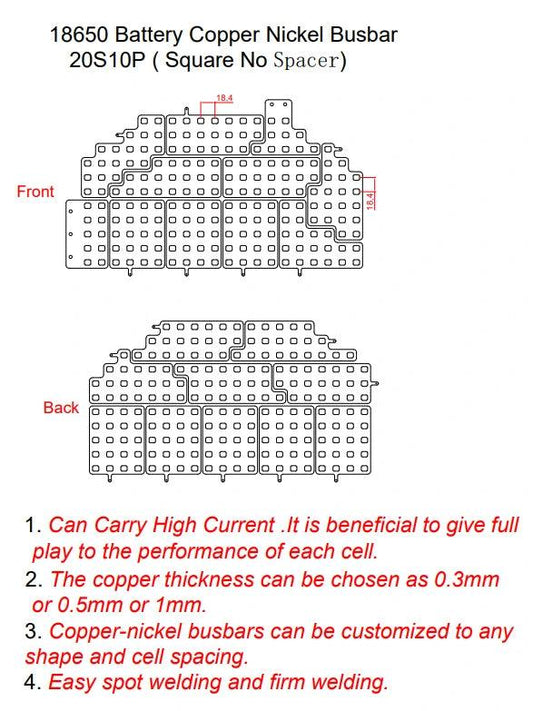

18650 Customized Copper Nickel Busbar 20S10P for Lithium-Ion Battery Connections in Electric Bicycle - No Cell Spacer

Vendor:Wellgo BatteryRegular price From $53.00 USDRegular price -

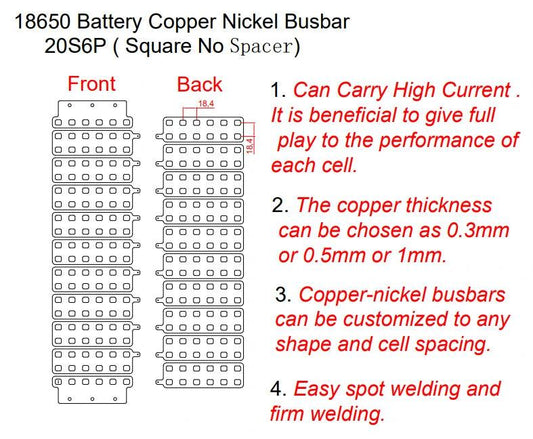

18650 Customized Copper Nickel Busbar 20S6P for Lithium-Ion Battery Connections in E-bike - No Cell Spacer

Vendor:Wellgo BatteryRegular price From $34.70 USDRegular price -

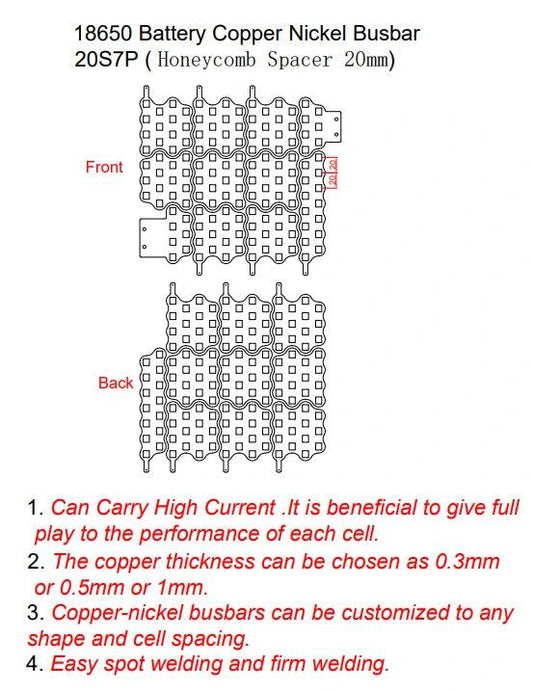

18650 Customized Copper Nickel Busbar 20S7P for Lithium-Ion Battery Connections in E-bike Honeycomb Cell Spacer Center - Distance 20mm

Vendor:Wellgo BatteryRegular price From $39.30 USDRegular price -

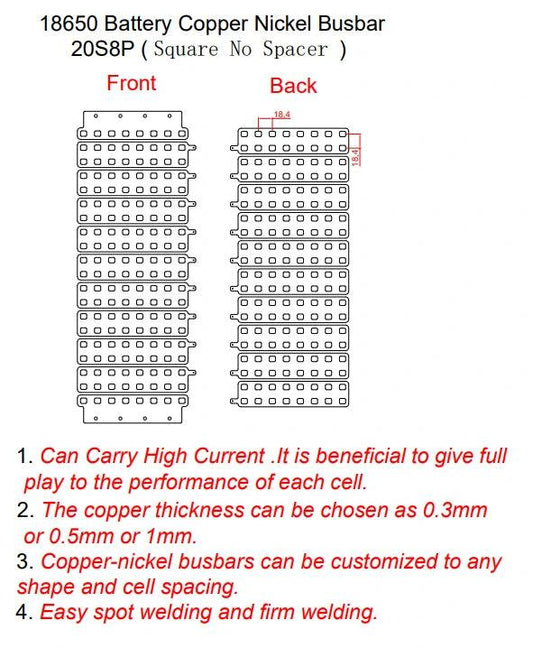

18650 Customized Copper Nickel Busbar 20S8P for Lithium-Ion Battery Connections in Electric Bicycle - No Cell Spacer

Vendor:Wellgo BatteryRegular price From $43.80 USDRegular price

Contact Us

"Connect to Thrive, Power Your Drive."

Wellgo is a trusted provider of high-performance battery connection solutions, specializing in custom-designed copper and nickel composite busbars, battery tabs, and precision connectors.

Precision Manufacturing and High-Quality Battery Connections

-

High-Quality Copper-Nickel Battery Busbars

Learn MoreWellgo’s copper-nickel composite busbars are engineered for superior conductivity and longevity, ideal for high-demand battery applications such as electric vehicles and energy storage.

-

Customized Laser Cutting Solutions

Wellgo’s skilled technicians use advanced laser cutting software to deliver customized designs, meeting unique requirements for each battery connection solution.

-

Advanced Laser Cutting for Precision Components

Our cutting-edge laser cutting technology ensures high precision in shaping nickel and copper battery connectors, providing consistent quality and fit.

Latest News

View all-

The Future of Busbar Technology in EV and Renew...

The future of busbar technology is reshaping how electric vehicles (EVs) and renewable energy systems deliver power efficiently and safely. With rising demand for high-current, compact, and sustainable energy solutions,...

The Future of Busbar Technology in EV and Renew...

The future of busbar technology is reshaping how electric vehicles (EVs) and renewable energy systems deliver power efficiently and safely. With rising demand for high-current, compact, and sustainable energy solutions,...

-

Export Guide: Shipping Copper Busbars to the US...

This article serves as a practical export guide for copper busbars shipped to the US and EU, covering customs, documentation, tariffs, and compliance requirements. It explains key regulations such as...

Export Guide: Shipping Copper Busbars to the US...

This article serves as a practical export guide for copper busbars shipped to the US and EU, covering customs, documentation, tariffs, and compliance requirements. It explains key regulations such as...

-

Copper Busbar Customization Options: Plating, B...

This article explores key copper busbar customization options — including plating, bending, and insulation — to enhance performance and reliability in battery busbar applications. It explains how surface coatings like...

Copper Busbar Customization Options: Plating, B...

This article explores key copper busbar customization options — including plating, bending, and insulation — to enhance performance and reliability in battery busbar applications. It explains how surface coatings like...