Nickel vs Copper: Which Battery Connector Works Best for Your EV Pack

Compartir

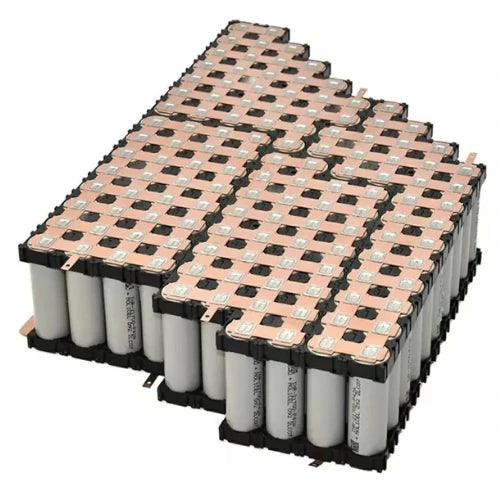

Introduction: The Right Battery Connector Can Make or Break Your EV Pack

If you're building or sourcing components for an EV battery pack, one crucial decision is choosing between nickel and copper battery connectors. The short answer? Copper connectors offer higher conductivity and are ideal for high-power applications, while nickel tabs are more corrosion-resistant and cost-effective for lower-current needs. This guide breaks down the pros and cons, backed by engineering research and real-world EV use cases.

Conductivity: Copper Is the Winner for High Power

Copper battery connectors provide excellent conductivity, around 59.6 MS/m, which is nearly 4 times more conductive than nickel, which sits at around 14.3 MS/m. This makes copper busbars ideal for high-current EV applications like fast-charging modules and drivetrain battery systems.

Corrosion Resistance: Nickel’s Strength in Harsh Environments

Where copper excels in conductivity, nickel battery tabs shine in corrosion resistance. In EV packs that may be exposed to humidity or oxidation-prone environments, nickel-plated connectors prevent rust and extend pack life. According to NASA Technical Reports Server (NTRS), nickel coatings perform exceptionally well in moisture-prone modules.

Cost Efficiency: Nickel Wins for Budget-Conscious Builds

For EV battery manufacturers balancing performance and cost, nickel strips are more budget-friendly than pure copper. In fact, copper prices have fluctuated dramatically due to global demand (Home | London Metal Exchange). Nickel connectors allow for scalable production without compromising base conductivity for mid-range current requirements.

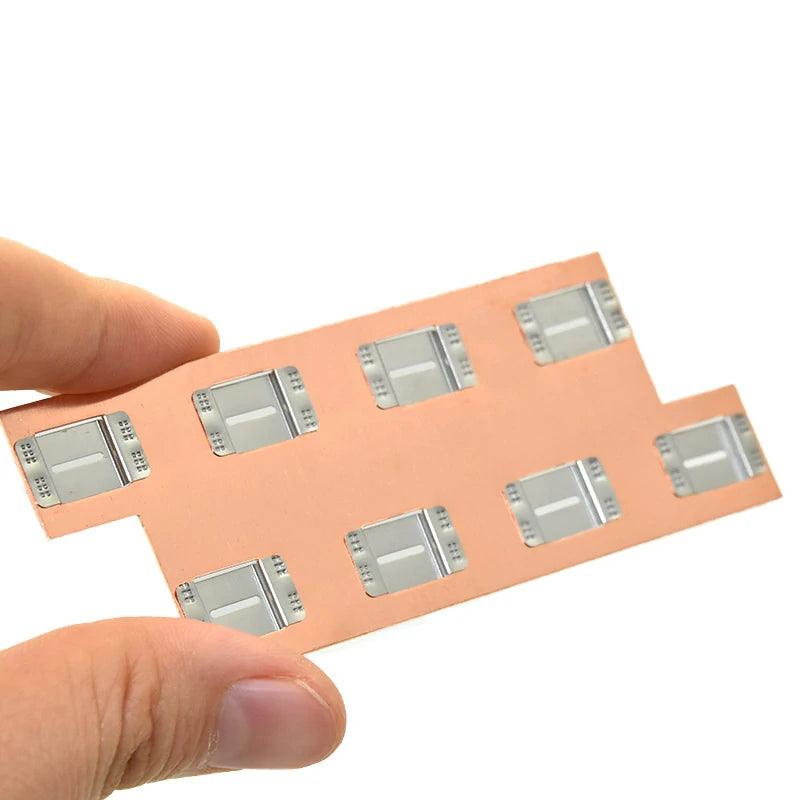

Weldability: Nickel Is Easier to Spot Weld

Battery pack builders know the pain of inconsistent welds. Nickel tabs offer smoother spot welding thanks to their lower thermal conductivity. This makes them ideal for 18650 and 21700 battery pack assembly, where manual or machine-based welding is common.

According to Home - Panasonic, using nickel-plated steel tabs can significantly reduce welding defects.

Thermal Management: Copper Handles Heat Better

If you're dealing with high-current discharge or fast-charging, copper busbars not only conduct electricity better but also dissipate heat more efficiently. Better thermal conductivity = longer battery life and safer operation. This is crucial in EV designs that rely on consistent cell balancing and temperature stability.

Data from Design and Experimental Investigation of a Self-Tuning Piezoelectric Energy Harvesting System for Intelligent Vehicle Wheels | IEEE Journals & Magazine | IEEE Xplore confirm copper’s superior thermal behavior in battery modules.

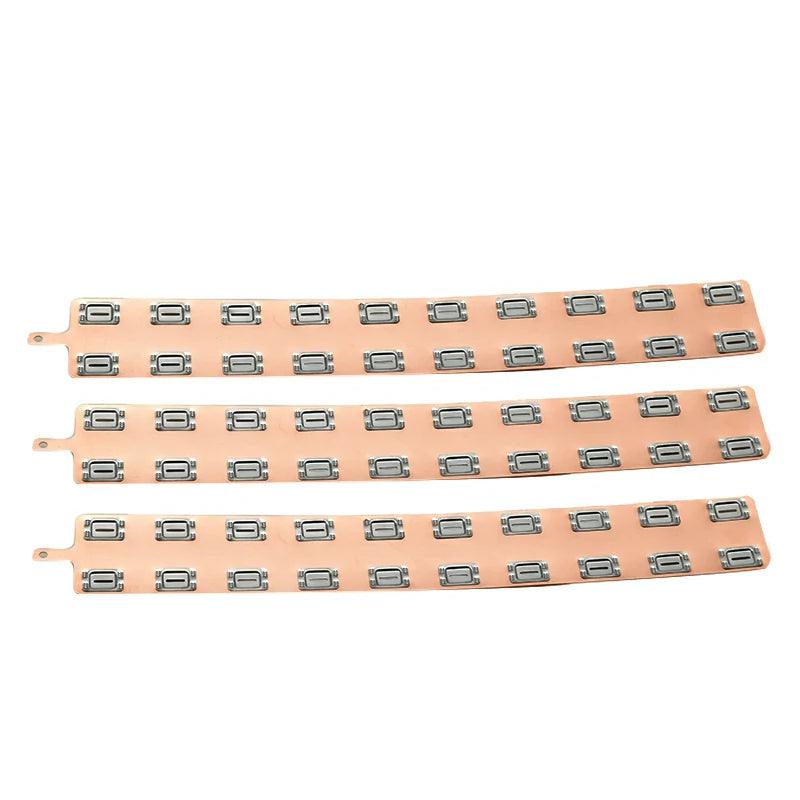

Hybrid Solutions: Copper-Nickel Combos for the Best of Both Worlds

Wellgo offers copper-nickel composite connectors, combining a copper core with a nickel-plated surface. These hybrid tabs achieve high conductivity while retaining corrosion resistance and weldability. They're especially useful in EV battery pack designs that face both high current and harsh environmental conditions.

Final Verdict: Choose Based on Your Application

There’s no one-size-fits-all answer. For high-performance EV battery packs, copper busbars or hybrid copper-nickel tabs are the way to go. For low-to-mid current modules, especially where cost and weldability matter, nickel tabs are a smart solution.

Contact Wellgo Battery for reliable, custom-manufactured nickel, copper, and hybrid battery connectors tailored to your EV battery needs.